01

金属包装材料标准生产流程ESTANDARD PRODUCTION FOR META

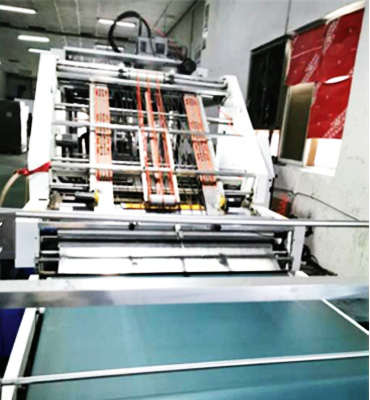

普朗工厂在过去几年发展中针对不同客户产品需求,完善生产流程和生产设备,公司拥有各类进口国产机器,包括半自动瓦楞箱成型机,全自动模切机,全自动贴窗机,高宝,小森,爱普生印刷机,注塑机,激光切割机,冲压机,自动焊接机等。

perlon factory has improved our production process and equipment according the product requirements from different customers. We have both imported production machines and domestic machines, including semi-automatic corrugators, automatic die-cutting machines and carton window patching machines, printing machines from Koenig-Bauer, Litherone, Epson, injection machines, laser cutting machines, punch machines and automatic welding machines etc.

perlon factory has improved our production process and equipment according the product requirements from different customers. We have both imported production machines and domestic machines, including semi-automatic corrugators, automatic die-cutting machines and carton window patching machines, printing machines from Koenig-Bauer, Litherone, Epson, injection machines, laser cutting machines, punch machines and automatic welding machines etc.

02

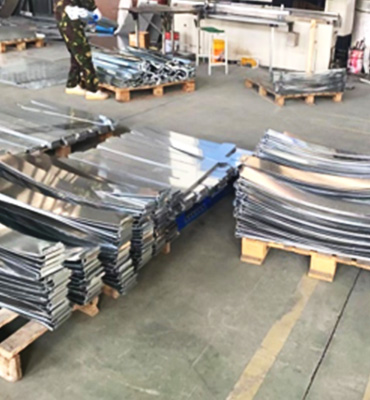

车间一角A CORNER OF WORKSHOP

金属托盘生产图。普朗工厂针对四类物流包装材料-纸质包装,塑料包装制品,木质和金属包装容器制定了标准化的生产流程,并接受非标包装定制生产。在前期商务洽谈阶段,普朗结合客户需求,综合分析供应链周围设备数据,进出频率和峰值数据,制定初步设计方案。经过客户审核和打样后,结合样品测试情况修改,客户满意后再进行批量生产。

These are the production pictures for metal pallets. perlon factory has made its standard production process for four kinds of logistic packaging materials with paper, plastic, wood and metal, and we accept custom production for non-standard packagings. At the stage of business negotiation, perlon will conbine customer requirements to make primary design after a comprehensive analysis for surrounding equipment data for supply chains, as well as in-out frequency and peak data. Then with the verifying of the design and sampling, there will be test and modification for samples. Bulk production will be followed after tests and modifications with the consent of customers.

These are the production pictures for metal pallets. perlon factory has made its standard production process for four kinds of logistic packaging materials with paper, plastic, wood and metal, and we accept custom production for non-standard packagings. At the stage of business negotiation, perlon will conbine customer requirements to make primary design after a comprehensive analysis for surrounding equipment data for supply chains, as well as in-out frequency and peak data. Then with the verifying of the design and sampling, there will be test and modification for samples. Bulk production will be followed after tests and modifications with the consent of customers.